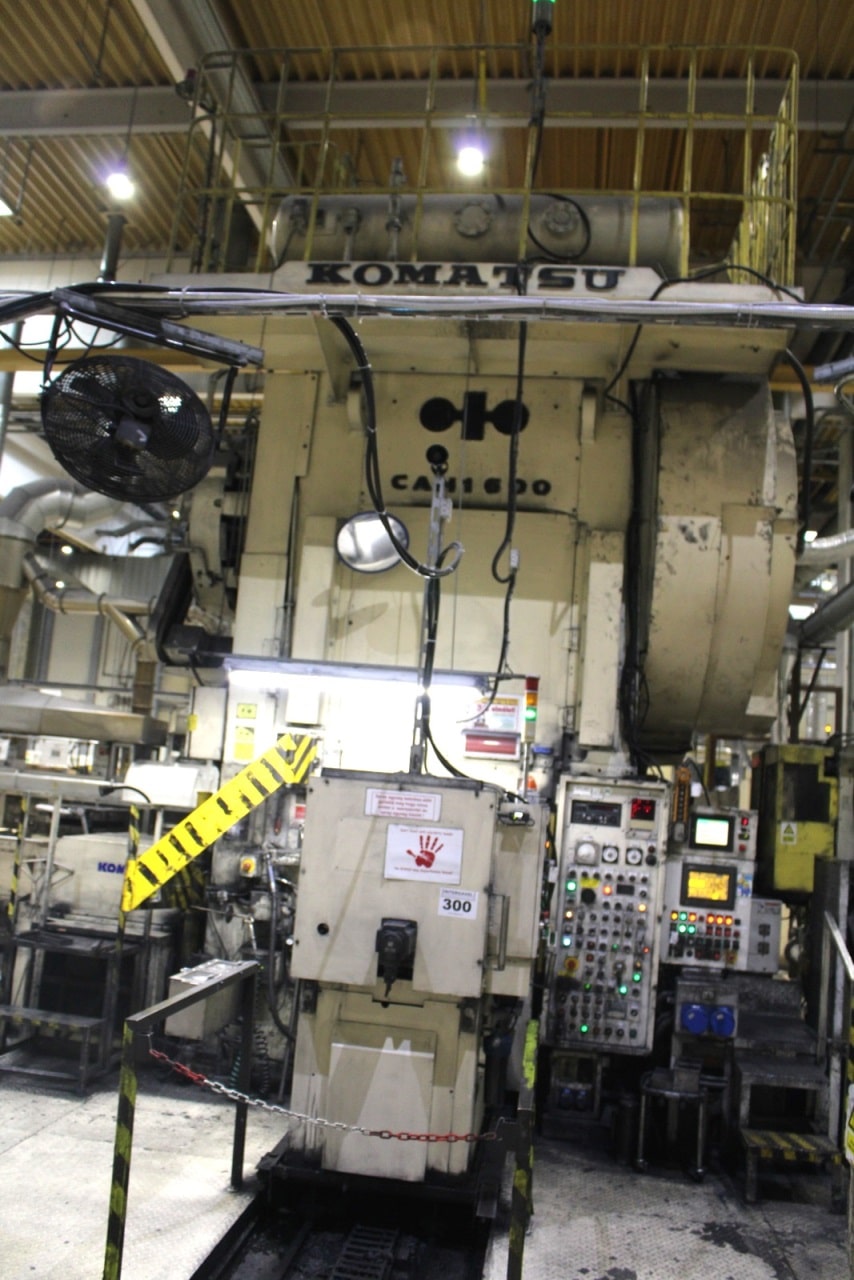

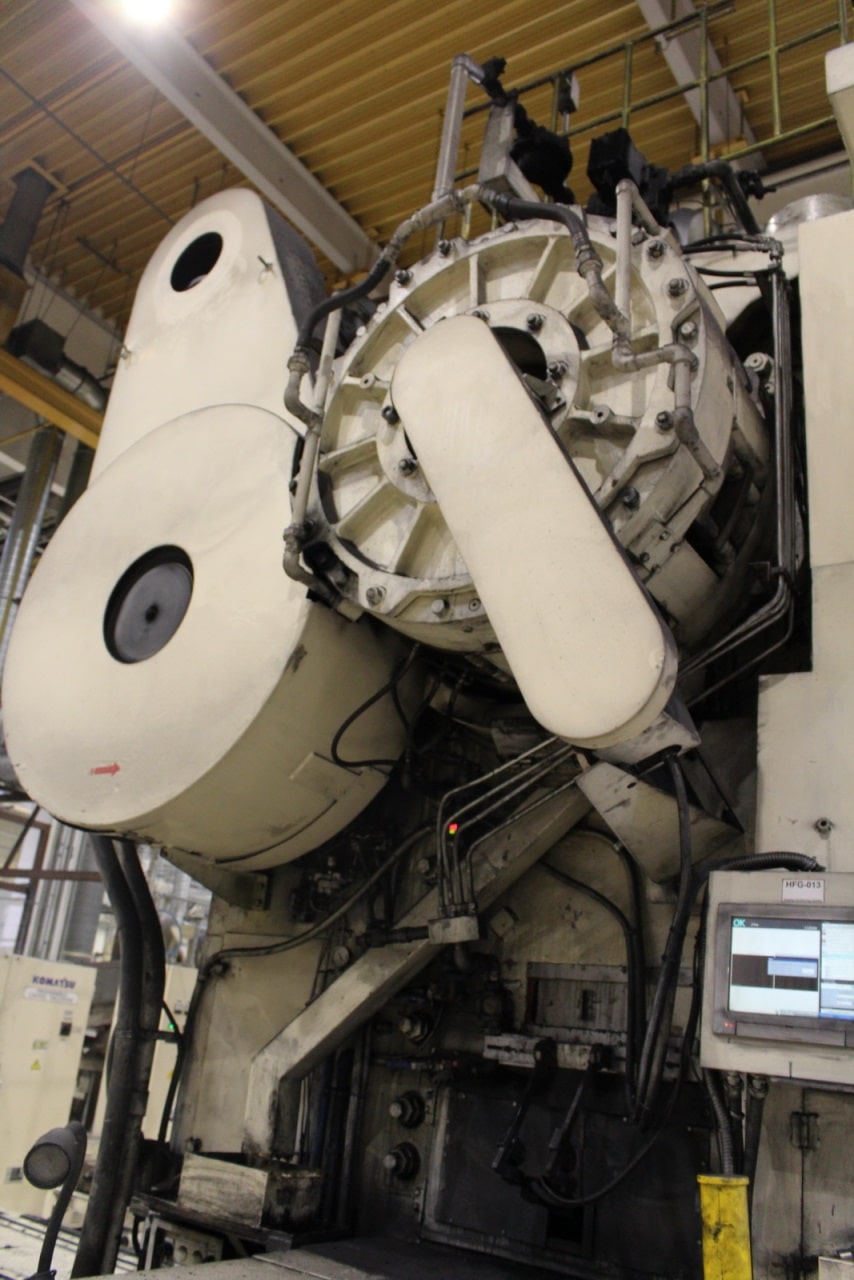

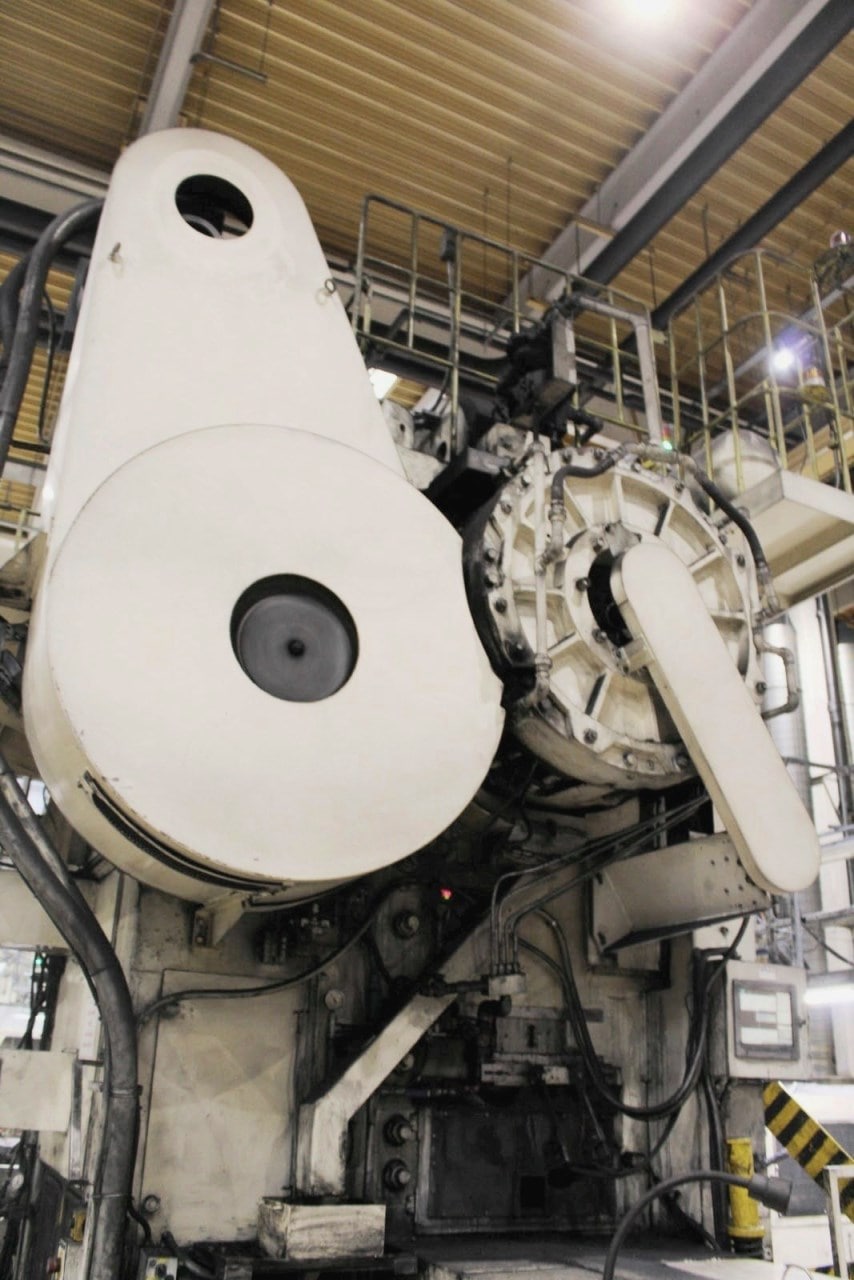

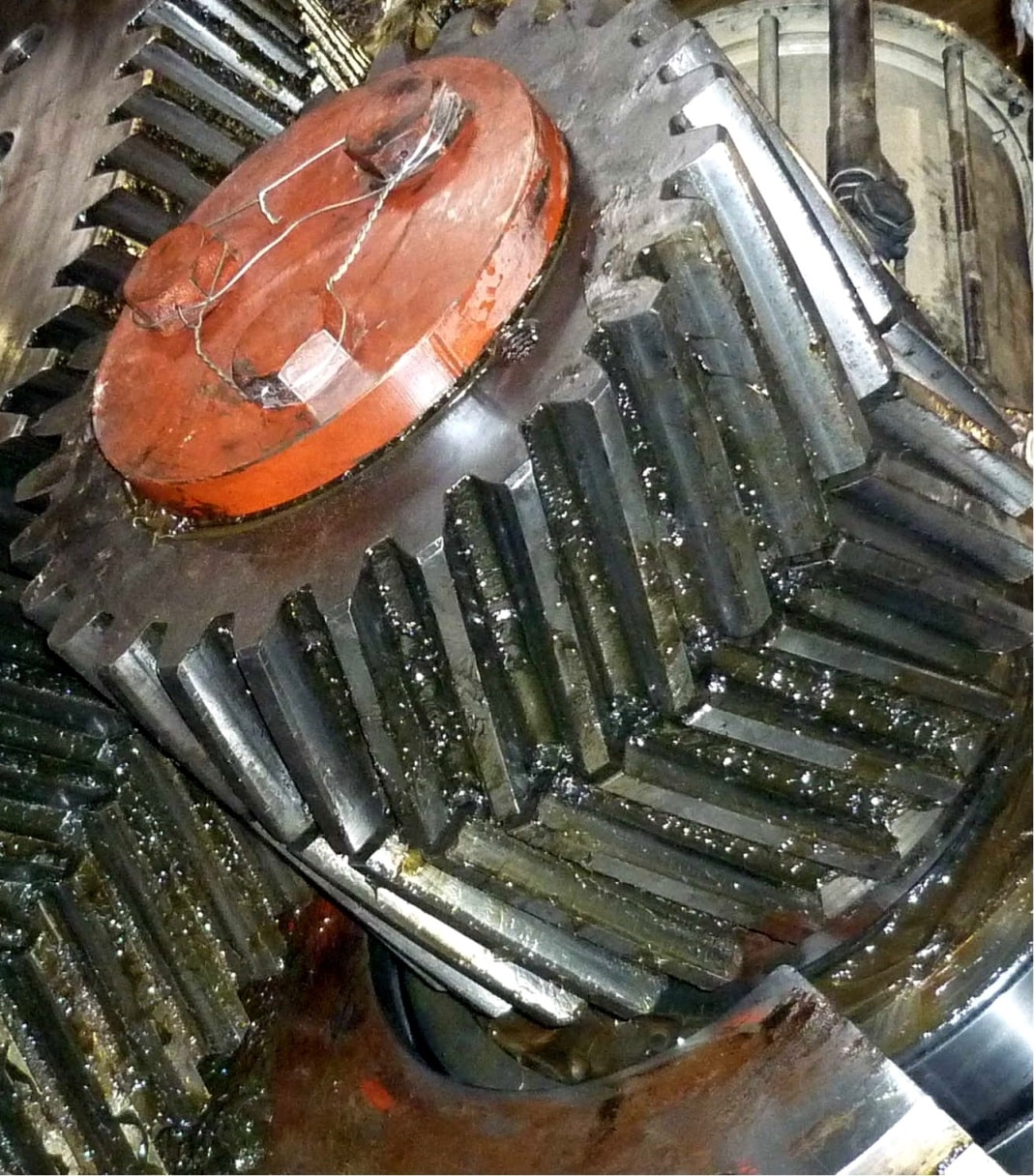

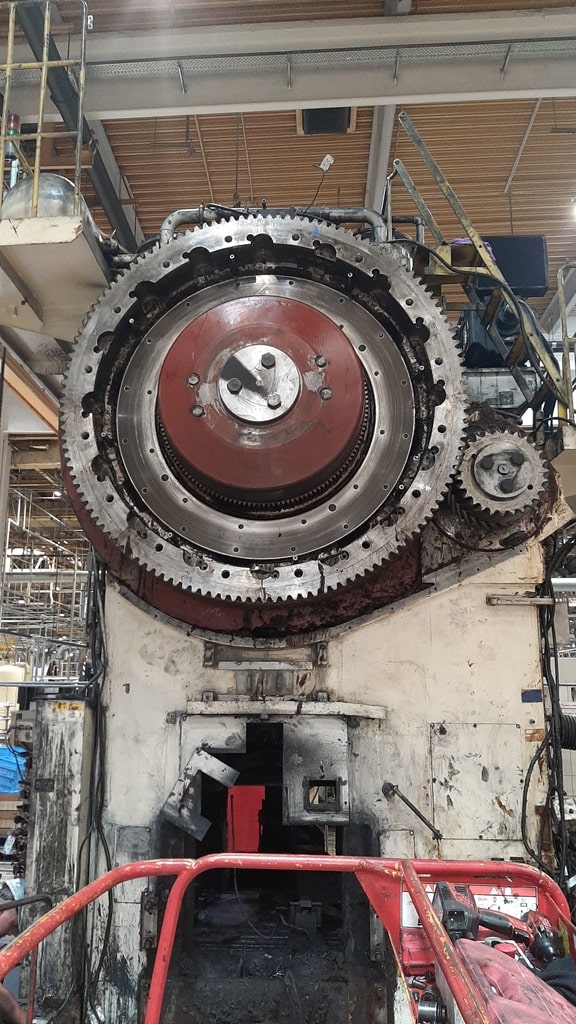

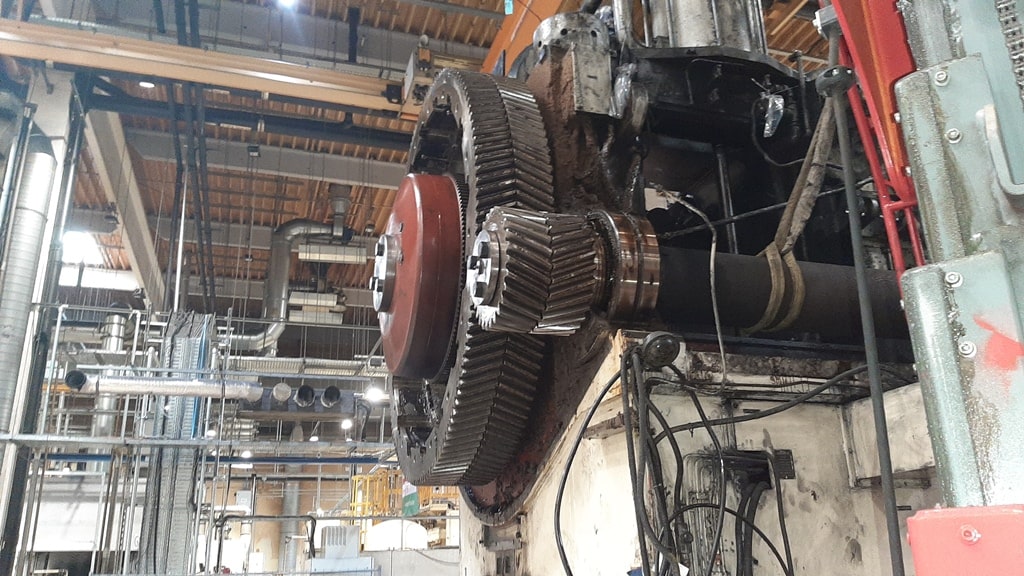

Hot forging press Komatsu CAH1600 - 1600 ton are used for production of precise die forgings with utilization in the automotive industry, for hot and semi-hot forging with forming forces of 16 MN.

This project included:

- technical inspection together with customers (in online / offline formats)

- test run

- preparation and organization of dismantling works

- supply of Hot forging press Komatsu CAH1600 - 1600 ton to the customer's plant

| Type | Hot forging press |

| Manufacturer | Komatsu |

| Model | CAH1600 |

| Overhaul | 2006 |

| Capacity | 1600 ton |

| Slider run | 280 mm |

| Adjustment | 12 mm |

| Closed height | 770 mm |

| Slider size | 950 x 900 mm |

| Table size | 1050 x 1350 mm |

| Distance between columns | 1170 mm |

| Side opening | 800 mm |

| Strokes per min | 20-40 |

| Ejector | 30 ton |

| Ejector stroke | 110 mm |